The weather has been unseasonably warm this autumn and early winter, but very wet as well. Today was an exception to that - clear blue skies, so Malc and I headed to Urmston & District Model Engineering Society track in Abbotsfield Park, with my 3.5" gauge Quarry Hunslet 'Alfred'

All pictures are copyright Jason Lau. Please click on any one for a larger image.

Abbotsfield park this morning. The left hand of the two tracks is the short inner running line we will be using. The main, much longer, running line passes along the far boundary.

Malc and I unloading the car on arrival at Abbotsfield Park this morning. I have already lifted Alfred from the car boot and placed him on the pneumatic platform. I doubt I could lift Alfred if he were any heavier, so for heavier locomotives the table can be raised and lowered by compressed air to match the height of a car boot so no lifting is required.

Alfred in the sunshine at Urmston this morning

Alfred in the sunshine at Urmston this morning

Alfred being pushed from the pneumatic lifting table onto the swing bridge which can be swung into place across the Society's running lines. Before the bridge can be swung across the lines, LED indicator lights on it must be checked to be 'green' and not 'red'. Red indicators show that a train is within two signals of the bridge, so one waits until it has passed, and the LEDs gone green, before swinging. Once the bridge is in place across the running line, signals are set to 'stop'. If an approaching train runs past the red signals while the bridge is across the line, a siren will sound alerting one to swing the bridge back out of the way immediately.

Alfred is pushed off the far side of the swing bridge towards the traverser, with the club house up ahead. The main running line crossed by the bridge can be seen to the left of Alfred. The line immediately to his right connects the carriage sheds with the main running line, the line to the right of that is the inner shorter track that Alfred will run on today. The two lines on the far right run to the loco preparation bays. All these tracks are inter-connected by the traverser just in front of Alfred.

I position the traverser so I can push Alfred onto it, move the traverser right to one of the prep bay lines, then push him up to the prep bays accessed via a second traverser. When the traverser I am using (above) is in use, it leaves a gap in the inner short track. To obviate that causing an accident, the traverser cannot be moved unless the token for the inner track is inserted into it. When driving a train on the inner track the driver must be in possession of the token. The driver's holding the token ensures it cannot be inserted in the traverser, so the traverser cannot be moved to leave a gap in the running line.

Meanwhile, Malc carries the tools, battery, and other stuff up from the car to the prep bay we will be using. The battery is to power the blower used to provide a draught up the loco's chimney until steam is raised and the loco's own steam blower can take over.

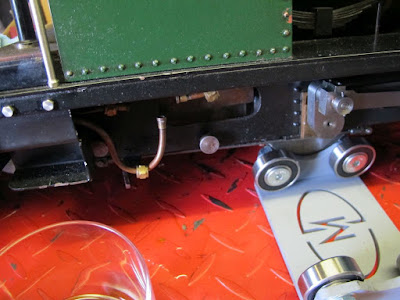

I begin preparation of Alfred on one of the prep bays. The tender with its 3 water connections (one for each injector and one for the hand pump) has yet to be attached to the locomotive.

The youngest Society member, Billy, works on his 'Polly' tank locomotive in the foreground while I work on Alfred on another prep bay. Malc is on his way to Alfred with the coal bucket to fuel-up the tender.

A 5" gauge Beyer Peacock tank engine arrives at the park. This loco is too heavy to lift so will make use of the pneumatic platform which will be set to the height of the car boot floor. The loco will be rolled out of the car onto the platform via a short metal bridging piece, then the platform height adjusted to match that of the swing bridge over the running line for the loco to be pushed to the prep bays.

Before a steam locomotive is ready, passenger services are run by the Society's diesel-outline electric powered locomotive. Here, a full train is ready to leave the station on the main running line while I approach on Alfred on the short running line.

Me driving Alfred on the inner running line with Malc looking on (he got to drive later), while the Beyer Peacock is on passenger carrying duties on the main running track. Other locos are being prepared on the bays in the background.

Me driving Alfred

Stepney shared the inner track with Alfred, here a delighted 6 year old handles the controls under direction of his grand dad!

The Beyer Peacock on the main running line which runs around the periphery of Abbotsfield Park.

Later 'The Beast' shared passenger duties, here driven by Keith. Malc and I have both driven this locomotive, and the Beyer Peacock tank engine which is sister engine to the one running today, on the main track on passenger trains with a qualified 'passenger' driver sitting behind us.

Stepney takes water on the inner track

The fascination of steam; a little boy and his dad are intrigued at the Beyer Peacock blowing off, as mum takes a photo.

Keith, with his mug of tea. The other chap, Fred, is the all-important ticket seller for passenger trains.

Fascination with steam (2); another little boy with his parents watch Keith firing 'The Beast'.

A view across the park this morning. The club house is on the left, the carriage shed just out of shot to the right. The main running line is in the foreground and runs around the entire park passing along the boundary visible in the far distance. The inner running line is much shorter. It is the one furthermost from the camera and runs along the hedge beyond the trees in the middle distance. The line in between these two goes to the carriage sheds.

Abbotsfield Park showing the club house at the top of the picture, the inner oval track in the top left hand corner, and the much bigger main running line around the periphery of the park. It's quite a trek for Alfred, with his little wheels, to journey around the big track!

Here's a video made by the youngsters of Urmston which tells the story of the Urmston & District Model Engineering Society.