Pictures from CVR Facebook page, by Frank Richards and Dave Gibson. Please click on any one for a larger image.

Cheddleton station in festive mood as families crowd the platform where the Santa Train awaits departure for Froghall

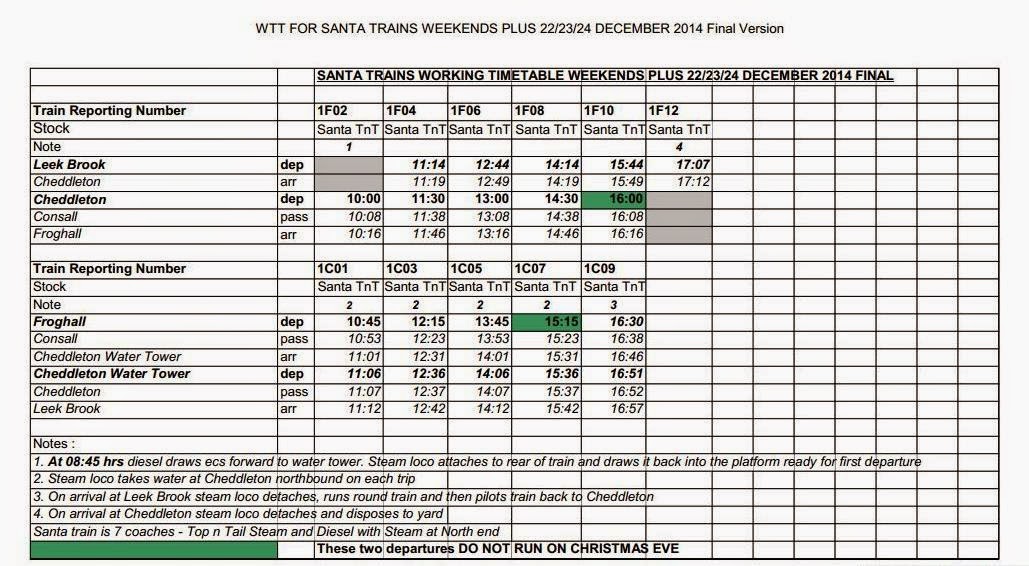

The Churnet Valley Railway are into the Santa Train season; a seven-coach train topped and tailed by the Polish Tank and Class 33 diesel 'Sophie'. The train runs for 11 days in December, including all this week up until Christmas Eve, and makes several trips up and down the line as this copy of the Working Time Table (WTT) shows.

Working Time Table (WTT) for this week (click on it for a larger image). The times that are significant for the Crossing Keeper are departures from Cheddleton water tower ('down' trains) and arrivals at Cheddleton ('up' trains), as these movements require the gates to be opened for the trains.

Crossing keeper is the first job I checked out in on the Churnet Valley Railway and a pre-requisite for training as a signalman in Consall box. Consall box is only used for days when two trains are running on the line, so they can cross at Consall, and there have been no such days on the railway since my last turn in the box in August see here. Kevin, who makes up the volunteer rotas, was desperate for Crossing Keeper volunteers this week so I put myself forward for today's slot.

There is a requirement for a Crossing Keeper at Cheddleton as Basford Hall Lane crosses the railway on a level crossing adjacent to the station. The Keeper's main job is to open and close the crossing gates for trains, and signal the trains across the crossing once the gates are secured open for the railway (and therefore closed across the road).

There is a fixed 'home' signal either side of the crossing at which the train must stop unless the Crossing Keeper gives the driver a yellow flag (yellow lamp in darkness, which was the case with the last two trains today) to authorise him to pass the signal 'at danger'. It is therefore a 'fail safe' system as the train will only proceed across the crossing if the Keeper has set the gates and given the driver authorisation to cross.

The Polish Tank gets away from Cheddleton as I stand by the opened (for the railway) crossing gates today wearing my 'grease-top' hat. The fixed home signals for the 'down' direction can be seen on the gantry, both at 'danger', but I have authorised the driver to pass the signal by use of a yellow flag.

I arrived at Cheddleton at about 08:20 this morning to unlock the crossing gates, fit the lamps to the gates, and switch on the 'annunciator' system which gives warning to the Keeper by sounding an alarm when a train is approaching in either the 'up' or 'down' direction. I was also able to help with shunting the train and locomotives ready for the day's services.

The annunciator alarm gives the Keeper time to stop any road traffic, open and secure the gates across the road, and prepare to give the train driver a yellow flag (or lamp) by the time the train is approaching the crossing. 'Down' trains don't stop at Cheddleton station, but run through to Leekbrook Junction, where they reverse, stopping at Cheddleton in the 'up' direction.

The Santa trains, unusually, are timetabled to take on water at Cheddleton water tower, just south of the station when travelling in the 'down' direction. The annunciator alarm can therefore be ignored for these trains, as there is no need to open the crossing gates for them until they are ready to leave the water tower for Leekbrook Junction. This is signalled to the crossing keeper by several loud blasts on the locomotive's whistle. Notice to open the gates for 'up' rains is given by the annunciator alarm in the normal way.

It can be seen from the WTT that the times of interest to the Crossing Keeper are the following:

'Up' trains departing Cheddleton water tower: 11:06, 12:36, 14:06, 15:36, and 16:51

'Down' trains approaching Cheddleton: 11:19, 12:49, 14:19, 15:49, and 17:12.

At the end of the day the Crossing Keeper switches off the gate lamps and annunciator systems, locks up the Crossing Keeper's hut, removes the lamps from the gates and places them in store, locks the gates 'open' for road traffic, and finally leaves the keys in Cheddleton signal box ready for the next Keeper tomorrow.

Here are a couple of pictures of the Santa train on the Churnet Valley line this week.

Here are a couple of pictures of the Santa train on the Churnet Valley line this week.

The Polish Tank clagging well as it gets the Santa Train away from Froghall. Note the rust on the rails of the adjacent loop line; with the train topped and tailed there is no need for the loco to run-round as usual, so the loop is not used.

Lovely Consall, site of 'my' signal box. This station is not used on the Santa timetable (a 'bah humbug! station according to stationmaster, Howard) so the train runs through without stopping. The seven BR Mk1 coaches and Class 33 'Sophie' on the back of the train can be seen in this picture.

Christmas Eve at Cheddleton. The Polish Tank leaves the water tower and heads for the crossing on its way to Leekbrook with one of Wednesday's Santa Specials.

.

.